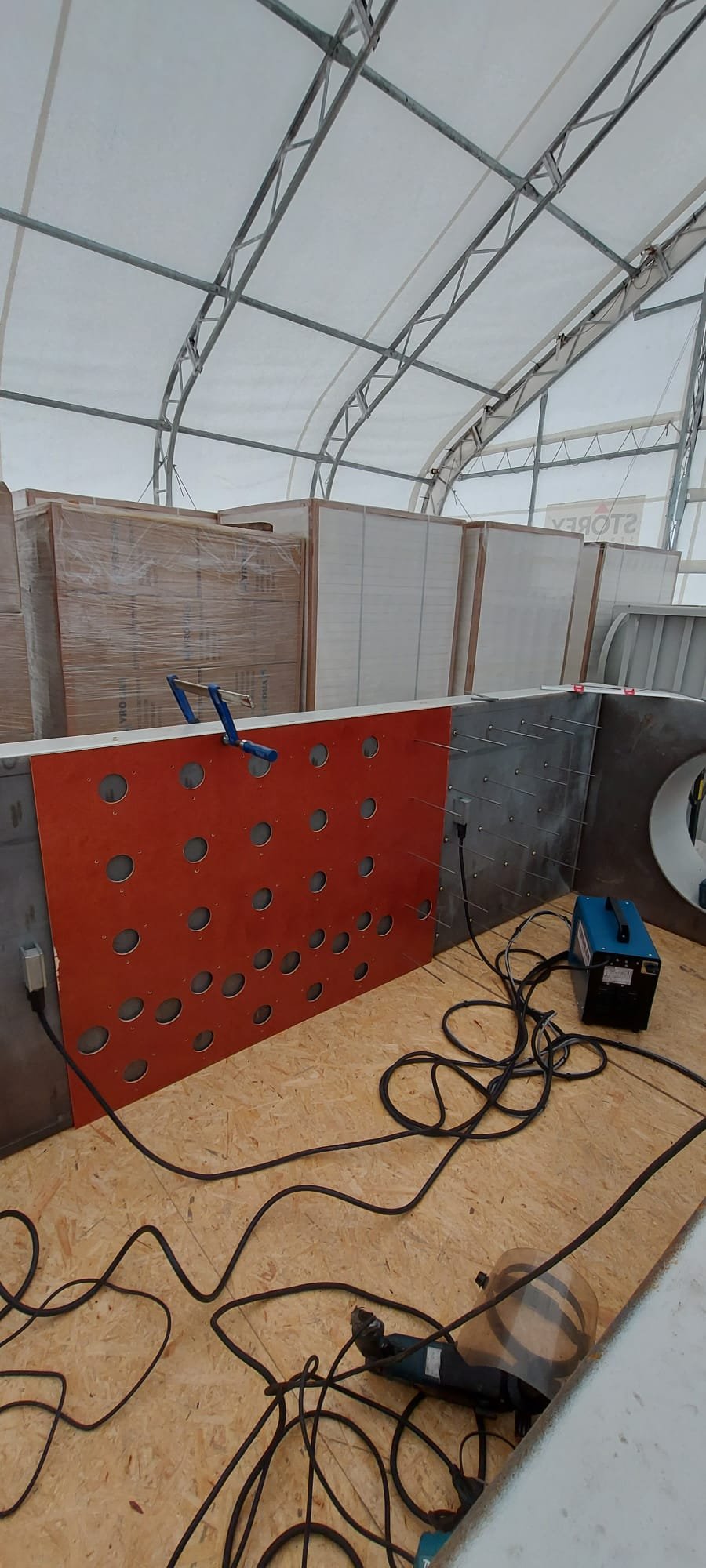

Pilot plant assembly within the LIFE IP project has started

Hyrogas has started the construction of an experimental pilot plant (TRL* 7) in the territory of the Dziļā Vāda landfill within the framework of the LIFE integrated project "Waste to resources Latvia – boosting regional sustainability and circularity" (LIFE Waste to Resources IP). Now, the development of the conceptual design has been completed, work on the development of the detailed design is underway, procurements are being made in parallel and the assembly of the pilot plant has started.

LIFE IP activity implemented by Hyrogas SIA aims at testing and demonstrating new recycling possibilities of non-recyclable fraction of municipal waste according to waste regeneration code R3. According to the Cabinet of Ministers Regulation No. 319 adopted 26 April 2011 “Regulations Regarding Waste Recovery and Disposal”, type R3 code is Recycling or reclamation of organic substances which are not used as solvents, including composting and other biological transformation processes and waste gasification and pyrolysis, using waste components as chemical substances, and shall be classified as code R3 corresponding waste recovery type of the regulation. Gasification and pyrolysis of waste, using waste components as chemicals, can be classified as a type of waste recovery corresponding to the R3 code. The activities under LIFE IP also include the development of policy recommendations for application of end-of-waste criteria for carbon based non-recyclables waste streams complying with all four end-of-waste qualification criteria:

1. the substance or object is commonly used for specific purposes;

2. there is an existing market or demand for the substance or object;

3. the use is lawful (substance or object fulfils the technical requirements for the specific purposes and meets the existing legislation and standards applicable to products);

4. the use will not lead to overall adverse environmental or human health impacts.

In a scope of the Hyrogas LIFE IP activity is planned to create a pilot plant, based on an innovative, patented technology, to process refuse-derived fuel (RDF) into syngas, with a processing capacity of up to 260 kg/h. The experimental prototype facility will test and demonstrate the processing of various mixed waste streams to produce syngas and vitrified ash meeting end-of-waste status criteria. The data obtained during the testing will be used both for the validation of the technology and for the development of the requirements of future legislative acts and will serve as a demonstration (pilot project) for other landfills in Latvia and other EU countries.

Thermal treatment, such as waste-to-fuel gasification, is a new waste transformation technology that makes the best use of the chemical components of the feedstock. RDF is a fuel obtained by shredding and dehydrating municipal waste after separation of inert materials (such as glass and metals) and is mainly composed of organic components of municipal waste, such as plastics and biodegradable waste.

The technology developed by Hyrogas engineers allows converting RDF into a gaseous energy carrier and turning waste into components as chemical substances. The application of gaseous energy carrier is very flexible, offering many advantages and possibilities of use in energy production systems, as well as in the production of high added value chemicals. The technological process is based on autothermal steam reforming of waste. Air and steam are used as a gasification agent in the technological process, integrating high and low temperature recuperation, which makes the process energy efficient and gives the opportunity to work with wet and non-homogeneous fuel, as a part of the obtained syngas is used to ensure the autothermal process. During the operation of the gasification plant, the only emissions are vitrified ash and condensed water.

Syngas, which meets the four end-of-waste status criteria of EU European Parliament and Council Directive 2008/98/EC, is planned to be used for industrial steam production, replacing natural gas, after prototype testing and technology demonstration. The use of vitrified ash is intended to be tested and demonstrated for the construction of waste landfill roads and mixing into concrete production in building industry.

*TRL - technology readiness level